Telsa has made a forefront drastic revolution on lithium-ion batteries, the company is aiming to make batteries even last-longer. In earlier of year 2019, Telsa has appointed Dalhousie University for creating a lithium-ion battery that can run a car for over 1 million miles which equivalent to over 70 years usage for typical car driving behaviour.

For current model 3 of Telsa, CEO Elom Musk claims that the car’s body and drive unit are built to las as long as a commercial truck, which can last up to 1 million miles while the battery can last up to 500,000 miles. However, the new scientific paper by Researchers of Dalhousie University, Dahn and his colleagues, detail a batter design that can run a million miles while just losing 10 percent of total battery capacity.

In near future, Tesla will test-run the new batter technology in their company’s cars, mostly probably will be the model 3, we assume. The researchers was publicly disclosing the properties of their design with the full cell design that including electrode compositions, electrolyte mixture, additives and etc. The detail of the study paper could found at ECS website.

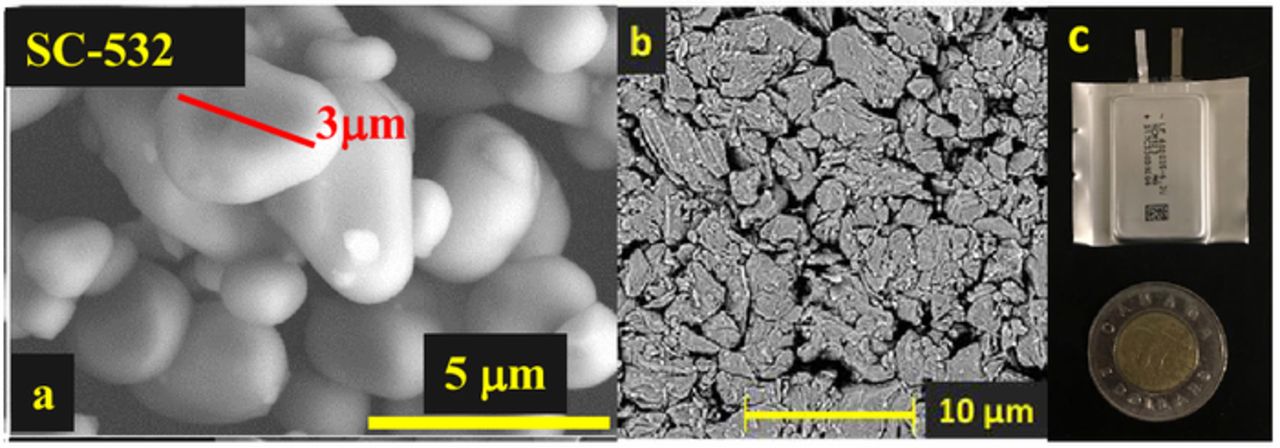

a) SEM image of the single crystal NMC532 powder (SC-532); b) Top view SEM image of the AML-400 negative electrode surface after compression; c) shows an image of one of the 402035-size pouch cells next to a Canadian $2 coin (a “toonie”).

The lithium-ion batteries described in the paper use lithium nickel manganese cobalt oxide, or NMC, for the battery’s positive electrode (cathode) and artificial graphite for its negative electrode (anode). The electrolyte, which ferries lithium ions between the electrode terminals, consists of a lithium salt blended with other compounds.

NMC/graphite chemistries have long been known to increase the energy density and lifespan of lithium-ion batteries. (Almost all electric cars, including the Nissan Leaf and Chevy Bolt, use NMC chemistries in their batteries, but notably not Tesla.) The blend of electrolyte and additives is what ends up being the subject of trade secrets. But even those materials, as described in the paper, were well known in the industry. In other words, says Matt Lacey, a lithium-ion battery expert at the Scania Group who was not involved in the research, “there is nothing in the secret sauce that was secret!”

Instead, Dahn’s team achieved its huge performance boosts through lots and lots of optimizing of those familiar ingredients, and by tweaking the nanostructure of the battery’s cathode. Instead of using many smaller NMC crystals as the cathode, this battery relies on larger crystals. Lin Ma, a former PhD student in Dahn’s lab who was instrumental in developing the cathode design, says this “single-crystal” nanostructure is less likely to develop cracks when a battery is charging. Cracks in the cathode material cause a decrease in the lifetime and performance of the battery.